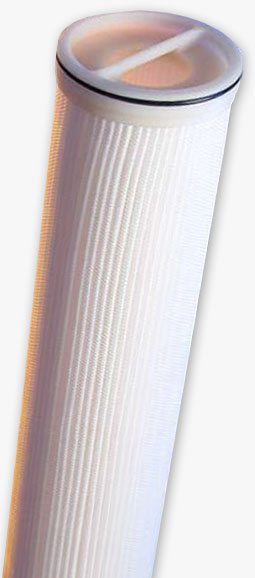

The series of filter elements of "High Flow" ÖloFPleat HFLO has been developed to be used in industrial processes that require filtration of large volumes of liquid, maintaining a low pressure drop and high solids holding capacity.

The ÖloFPleat HFLO is manufactured with a depth filter media which in turn is folded to increase the effective filtration area and thus easily handle large flows at a high efficiency. Its arrangement of pleats is structurally reinforced to ensure that their rigidity and integrity are maintained when maximum operating levels are achieved. ÖloFPleat offers two options HFLO filter media, PP and GP. The PP option provides a filter element made of 100% polypropylene, it built from a degree of filtration for CRY (100% retention of Cryptosporidium) designed for applications in the food and beverage field and ends with a more coarser degree of 90 for multiple industrial applications. The option GP made of micro fiberglass is designed for applications involving fluids and temperatures not compatible with polypropylene. All components are sealed by a thermo-welded processes eliminating the use of adhesives, optimizing the integrity of the filter element.

Features

- High product quality that meets the requirements for food contact according to the European Regulation ( EC ) Number 1935/2004

- Materials meet requirements for US FDA Title 21

- Large filter surface that offers a lower initial pressure differential and an excellent retention of pollutants.

- Absolut filtration with efficiency of 99.98% (β of 5,000).

- Construction 100% thermo-welded to ensure maximum integrity and structural integrity.

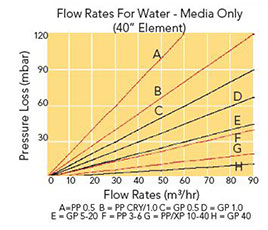

- Hi flux range up to ≥ 109 m³/h.

- Internal central support, unique in hi flux filters to ensure integrity at high pressure and flux.

- Lower maintenance stops and fewer numbers of filters needed.

- Version XP (Extended Life) for applications with large volumes of solids.

- Available form 0.5 a 90 microns, rating Beta 5000.

- Dramatically reduces the space normally used by conventional filtration systems.

- The geometry of its pleats are specifically designed to flow inside out, keeping all contaminants within the filter element.

- Broad chemical compatibility.

Standard Applications

Food and Beverage: Bottled water, beer, wine, polishing filters, clarification.

Pharmaceuticals: Solvents discharge, raw water intake.

Chemicals: Acids, bases, solvents and polymers.

Water Treatment: Pre-filtration for Reverse Osmosis, protection for U.V. systems, resin tramps.

Oil & Gas: Water injection systems, amines and glycol flows.

Sterilization and Sanitization

Steam or Autoclave: 121°C (10 cycles).

Hot water: 90°C for 30 minutes.

Construction elements

- Media:

- PP- Polypropylene

- GP- Borosilicate glass fiber bonded with epoxy resin

- Cover, core and caps:

- P- Polypropylene entirely

- S- Caps of polypropylene, cover and core of 304 SS

- N- Nylon caps, cover and core of 304 SS

Product Dimensions

- External diameter: 160 mm

- Internal diameter: 75 mm

- Filtering area: (for each 40” element):

- PP: 8 - 10.3 m2

- GP: 6.2 - 6.7 m2

- XP: 4.9 m2

- Length: 20’’, 40’’, 60’’

- Connections: Flanges

Operating conditions

Temperature

Recommended:

PP: 80°C

PS /PN: 100°C