Commonly compressed air should be as clean as possible to ensure the pneumatic equipment's life. The protection of your system is essential, air could be polluted dust, dirt, oil and water. This contaminants will wear down equipment parts like engines and other support systems.

There are many different kinds of filters and housings, and selecting the right one can be difficult. At Ölof Filtration Teknologerna AB we have a multidisciplinary team of engineers witch will assist our clients to fin the best one for taking in consideration quality, maintenance stops and other filtering

characteristics.

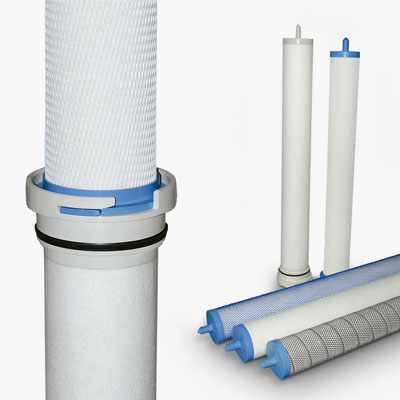

Particulate filters

The most common contaminant in compressed air will be particulates. This filters will work to remove dust, dirt and other particles.

Coalescing filters

This type of filter induces a coalescing effect to the liquids present in the compressed air to capture it. This system can also eliminate some degree of dust and dirt from the compressed gas.