ÖlofDeep AP Filter Cartridges are constructed with gradient pore diameter of spray nozzle which enables a "multi-layer" media. This Polypropylene structure is functioned with fine fibers in the inner layer and coarse fibers in the outer one which constitutes four different pore diameter in order to filtrate particles in different layers. This design has a high contaminant holding capacity, which also ensures a longer service life and a low pressure drop.

Features

- Multi-layer structure cartridge

- High contaminant holding capacity, long service life

- 100% PP for compatibility with a wide range of process fluids

- Micro-denier melt-blown filtration fiber, high removal ratings

- Formed by thermal bond without use of any binders and adhesives

- Certificated by NSF42 and FDA CFR Title 21.

- In compliance with the latest EC Directive for food contact

- High void volume, resulting in low clean Δp and excellent dirt holding capacity.

- End cap welded direct to the core for extra security and strength.

- Thermally bonded fiber matrix minimizes fiber migration.

- One piece construction up to 1524mm (60").

- Advantage grade featuring molded end caps and rigid outer support cage.

- Optional glass filled core and end caps for high strength / temperature applications.

- 100% polypropylene or nylon 6.

- Materials meet US FDA Title 21 and USP Class VI requirements (PP Only).

- Meets the requirements for food contact as detailed in European Regulation (EC) Number 1935/2004 (PP Only) Absolute removal ratings for consistent and reliable performance.

- Graded density structure for maximum dirt holding capacity.

- Increased void volume giving high flow rates and low initial pressure losses.

- Wide chemical compatibility using optional materials, polypropylene and nylon 6.

- Range of Absolute ratings from 0.3 to 180μm (Beta Ratio 5000).

- Thermal bonding process minimizes media migration and ensures minimal extractable.

- Identification data embossed on every cartridge.

- Advantage grade featuring molded end caps and rigid outer support cage.

- Elements are available up to 1524mm (60”) in length, either double open ended or with most common end cap fittings.

Standard applications

- Food & Beverage: Bottled Water, Flavored Water, sugar syrup, juices, etc.

- Water Treatment: Membrane protection, Resin traps, production water.

- Oil & Gas: Amine control, glycol, completion fluids, Pre-RO and Pre-DI water.

- Other: High viscosity fluid, Paintings, galvanoplasthia.

Operational Data

- Maximum temperature: 80°C

- Maximum differential pressure: 20°C: 70 Psid (4.92 kg/cm²)

- Recommended replacement pressure drop: 35 Psid (2.4 kg/cm²)

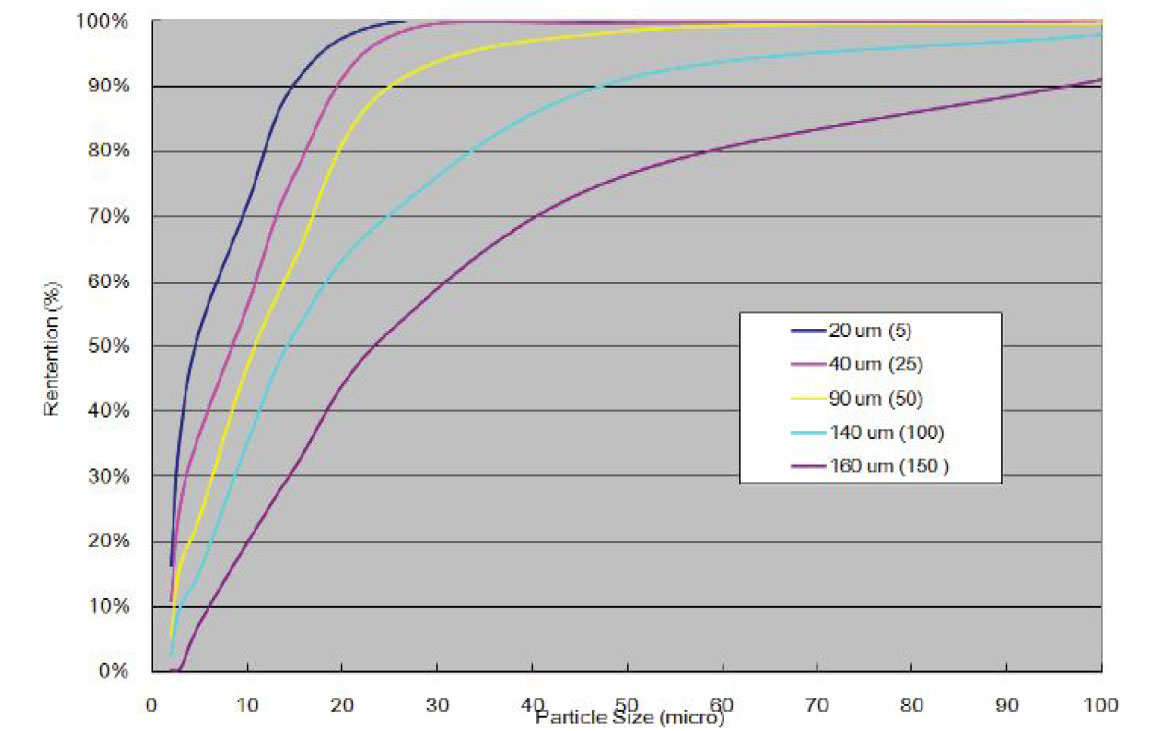

Efficiency of Filtration

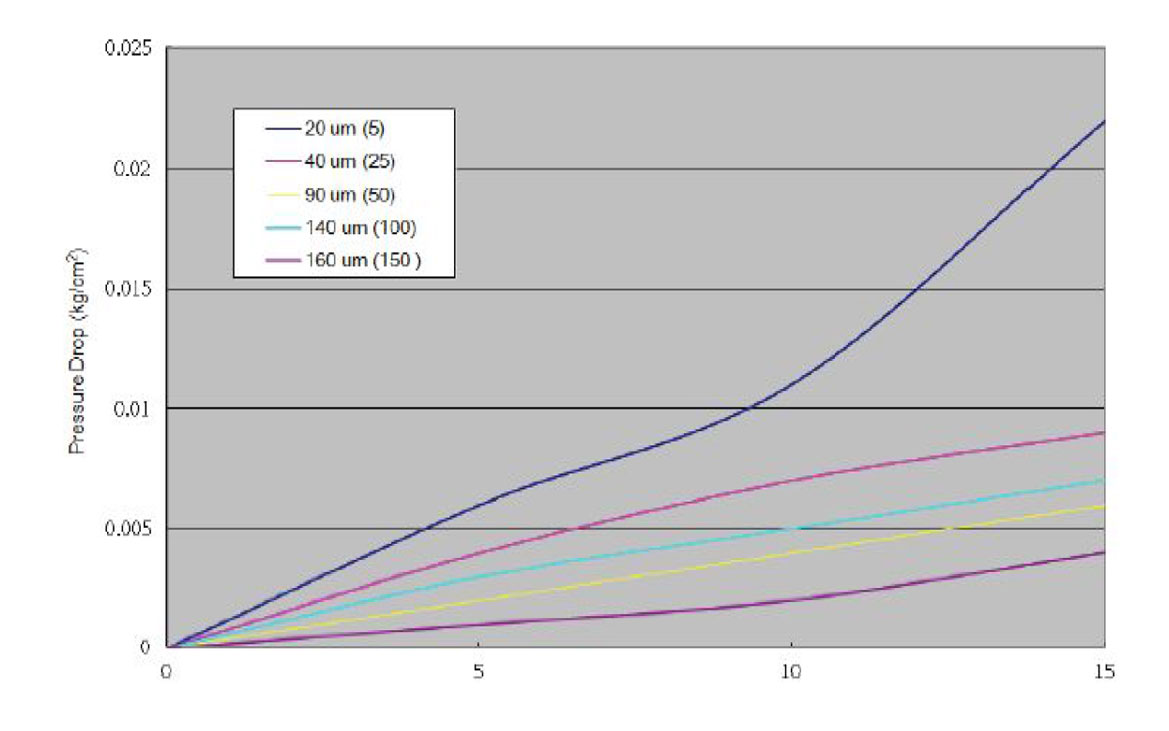

Initial Pressure Drop

Ordering Guide

Type

AP

Outer Diamter

M – 65mm

Inner Diameter

B – 28mm

Rating (μm)

001 – 1μm

005 – 5μm

020 – 20μm

050 – 50μm

075 – 75μm

100 – 100μm

150 – 150μm

005 – 5μm

020 – 20μm

050 – 50μm

075 – 75μm

100 – 100μm

150 – 150μm

Length (inch)

0987 – 9,87"

10 – 10"

20 – 20"

30 – 30"

40 – 40"

10 – 10"

20 – 20"

30 – 30"

40 – 40"

End caps

B: Double Open

F: Double open & cap (DOE)

0: 222 with Flat End (SOE)

5:222 with Fin (SOE)

6:226 with Flat End (SOE)

7:226 with Fin (SOE)

F: Double open & cap (DOE)

0: 222 with Flat End (SOE)

5:222 with Fin (SOE)

6:226 with Flat End (SOE)

7:226 with Fin (SOE)

O-ring Material

S-Silicone

E-EPDM

N – Buna N

A- PE (gasket

only)

V-Viton

T-PFA

encapsulated

Viton

Inner Core

P -Polypropylene