ÖlofDeep filter cartridges are constructed with a “multi-layer” gradient pore structure with fine fibers in the inner layer and coarse fibers in the outer layers providing prefiltration and final filtration on the same element.

ÖlofDeep progressive media technology assures total use of the gradient depth of the cartridge, providing longer service life, maximizing dirt-holding capacity at extremely low differential pressures.

ÖlofDeep F&B filter´s fibers are blown continuously onto a central support core, with fiber diameters controlled to produce different pore sizes throughout the extrusion process.

All the layers are inter-linked to offer maximum support while ensuring that the high void volume is maintained, but with increasing fiber density towards the cartridge central core – therefore resulting in true depth filtration.

Features

- Designed for Food and Beverage applications

- Multi-layer structure cartridge

- Long service life

- 100% polypropylene for compatibility with a wide range of process fluids

- Micro-denier melt-blown filtration fiber, high removal ratings

- Formed by thermal bond without use of any binders and adhesives

- Certificated by NSF42 and FDA CFR Title 21

- In compliance with the latest EC Directive for food contact

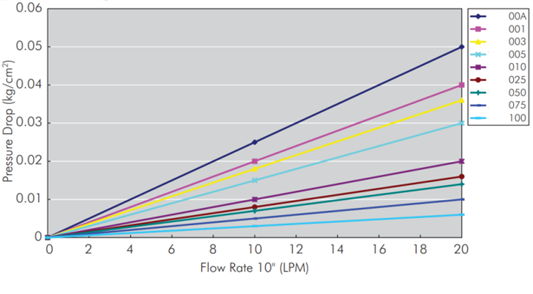

- High void volume resulting in low clean Δp and excellent dirt holding capacity

- End cap welded direct to the core for extra security and strength

- Thermally bonded fiber matrix minimizes fiber migration

- One piece construction up to 40"

- Graded density structure for maximum dirt holding capacity

- Increased void volume giving high flow rates and low initial pressure losses

- Thermal bonding process minimizes media migration and ensures minimal extractable

Food & Beverages applications

Bottled water, Beers, Wines, Flavours, Polishing lines, Clarification.

Water treatment applications

Potable water, Resin trap, Pre/Post UV, Membrane protection.

Dimensions

- Outside Diameter: 63mm

- Core Diameter: 28mm

Maximum Operating Conditions

- Temperature: 80ºC

- Recommended change-out differential pressure: 2.1 Kg/cm2

Sterilization and Sanitization

-

Steam:

- 121ºC for 15 mins (20 Cycles)

- 135ºC for 30 mins (5 Cycles)

- 90ºC for 30 mins (0.2 bar Δp max)