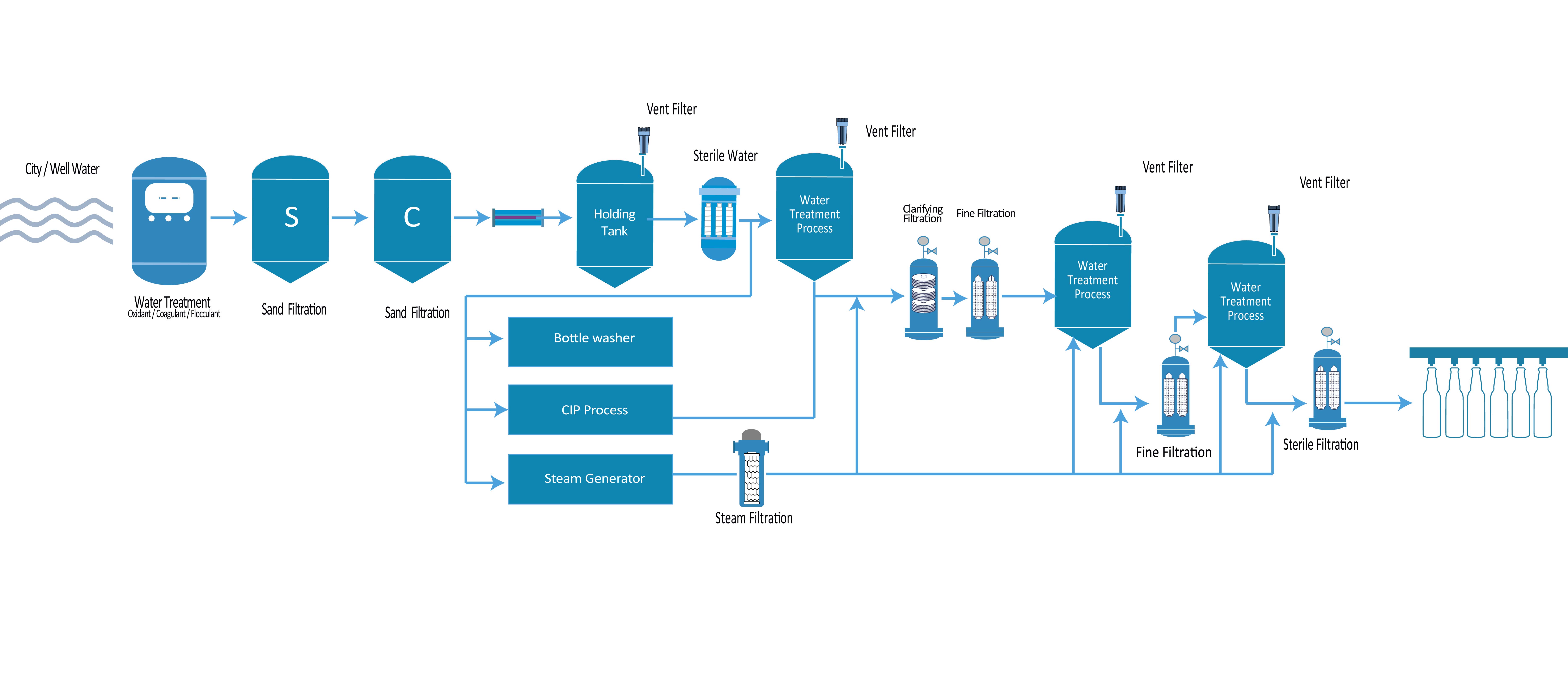

In the main brewing process, several stages of filtration are required and pore rating, pressure drop, removal of byproducts, sterile venting, gas filtering and other specific needs have to be carefully checked.

In each filtering stage, from Trap filtration system to final filtration, Ölof Filtration Teknologerna AB will deliver the best designed solution to ensure the best product.

We invite you to be a part of our list of satisfied costumers, our engineers will help in designing the best filtering system for the best product.

Ölof Filtration Teknologerna AB Filtering solutions

In beer-making the process must meet high standards to preserve freshness, taste, color, odor and other distinctions of beer. We in Ölof Filtration Teknologerna AB are constantly working in our R&D to keep update with the industry requirements and new developments.

We know that filtration plays a big part to maintain an uniformity in taste, color and in every aspect of the final product batch after batch.

Generally there are four main clarification stages including primary filtration, trap filtration, fine filtration and final membrane filtration. Filtration at each stage is for a particular purpose:

- Clarifying filtration removes solids and bulk yeast from the beer.

- Trap filtration removes Diatomaceous earth or other process additives.

- Fine filtration may reduce yeast level and removes fine particulates that could foul a final membrane filter.

- Final membrane filtration removes organisms (bacteria and yeast) that could spoil the packaged beer.