Ölof Filtration Teknologerna AB keeps growing and professionalizing its solutions in a wide number of industries. In the vegetable oil industry our engineers have accomplished the task to chose the ideal filters to enhance the quality of the final product.

Filtration improves the overall quality of the oil by eliminating suspended solids that can end at the bottom of the bottles and polishing the fluid to prevent a hazy look. It is also important to prevent the emulsion of the product by tanking careful care of the type of media used and the differential pressure in the filtering process.

Another benefit of oil filtration is the reduction in moisture content. Moisture in the

oil gives a dulling affect and also assists in forming sediments from impurities in the

oil.

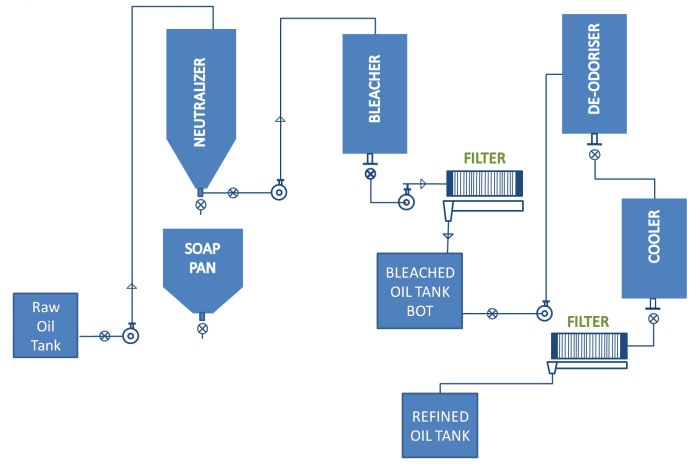

Basic filtration process

Filtration steps

Ölof Filtration Teknologerna AB gas developed a series of filters for each kind of filtration needs in the Edible Oil industry. We even customize filters for individual needs.

Depending on the type of oil and final purpose, the oil is processed in a sequence of process steps which can be divided as follows:

- Crude oil filtration for removal of foots.

- Miscella filtration for production of lecithin from gums.

- Bleached and / or detoxified oil filtration to remove colour and other components.

- Winterised oil filtration to remove waxes to enhance cold stability.

- Catalyst filtration to remove nickel catalyst after hydrogenation of the oil.

- Residual catalyst filtration to remove solid nickel catalyst after transition to nickel soaps.

- Deodorised oil filtration to remove impurities formed during mmm deodorisation.

- Safety filtration to improve filtrate quality and/or to protect mmm sequential equipment.

- Polishing filtration to improve product quality