The ÖloFCarbo F activated carbon products are specifically designed to attend the toughest applications that the oil and gas industry has to offer. By using only the highest quality materials and the most robust designs, ÖloF guarantees a finished product second to none.

| Model | OD | HT | ID |

|---|---|---|---|

| CVF 1120-C | 10.75" | 20.25" | 2.06" |

| CVF 1122-C | 10.75" | 22.25" | 2-06" |

| CVF 636 | 6" | 36" | |

| CVF 636-610 | 6" | 36" |

CVF series activated carbon canisters

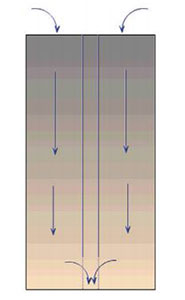

Ölof Carbon Vertical Flow activated carbon canisters increase fluid contact by eliminating the potential bypass in using the relatively thin bed available in a radial flow configuration. Ölof CVF 1120 and 1122 canisters outlast the radial flow design by 30%.

| Model | OD | HT | ID |

|---|---|---|---|

| CRF 1120-C | 10.75" | 20.25" | 2.06" |

| CRF 1122-C | 10.75" | 22.25" | 2-06" |

| CRF 720 | 6.63" | 20" | 1.5" |

| CVF 636-610 | 6.63" | 22.5" | 1.5" |

CRF series activated carbon canisters

The Ölof CRF Radial Flow activated carbon canisters present a greater superficial area to the process fluid, lowering velocity to better deal with high solids contamination.

Bulk activated carbon

Ölof activated carbon is specially selected to maximize performance in gas processing applications where the target contaminant is long chain hydrocarbon molecules. Used in all Ölof carbon canisters, it is also available in bulk form, in 44 lb bags, and 880 lb super sacks.

Hardness

The Ölof activated carbon hardness number of 90 is significantly harder translating to less particle attrition and carbon fine generation during transportation, replacement, and use than the leading manufacturer. Always remember to use an accepted rinsing procedure for the best service possible from your Ölof activated carbon product. In the right quantity, coal fines can contribute to foaming issues.

Pore structure

The primary function of Ölof carbon in oil and gas applications is to remove long chain hydrocarbons. The molasses number is a good indicator for predicting how well an activated carbon will adsorb higher molecular weight organics. Ölof molasses number is based on a standard test. A molasses decoloring efficiency (DE) of 85 converts to a molasses number of approximately 400. This number indicates a great performance in adsorbing higher molecular weight organics.

The iodine number is an excellent parameter to determine the overall surface area of activated carbons, but it also is a great indicator of how well a carbon will adsorb organics. Ölof activated carbon has a minimum iodine number of 1000, while the leading lignite based 8X30 mesh carbon is approximately 500. Our activated carbon has an iodine number double to that of the leading lignite based 8X30 allowing for superior adsorption capability.

Operating conditions

Factors affecting carbon performance include temperature and contact time in addition to the type of carbon and the targeted contaminant. The maximum recommended operating temperature for carbon is generally 120O°F as exceeding 150O°F can greatly reduce capacity in hydrocarbon capture levels.

Similarly, high rates of flow or reduced contact time diminish the ability of the carbon to capture and retain contaminants. Unnecessary abrasion can also be an additional side effect.

A carbon unit should always be protected upstream and down by adequate particulate filtration to prevent fouling of the bed and to prevent any carbon fines from entering the system. In a properly designed system, the carbon unit should not develop any significant differential pressure over time.

Other features of Ölof activated carbon

The leading lignite based activated carbon manufacturer acid wash their carbon with hydrochloric acid and rinses it. As a result, an acidic residual remains on the carbon leaving a typical pH value of 4.5. Ölof activated carbon is not acid washed, it will not decrease the pH of an Amine stream.

Total ash content measures the non-carbon portion of an activated carbon. As the ash content of the leading lignite based carbon is almost twice that of the Ölof carbon, there is a much higher potential that compounds within this ash may dissolve within the fluid being treated.

Also Ölof activated carbon contains 7% less water than the leading lignite based activated carbon. Less waters translates to more carbon in every shipment.