Ölof Filtration Teknologerna AB embraces today´s demand of products capable of seamless performance in a variety of conditions under the harshest environments. The SecureLock filters versatile separation system offers superior contaminant removal and coalescing efficiency with the added feature of our patent pending SecureLock locking mechanism. This feature gives the ability to customize cartridges , as needed, to suit specific operating conditions or changing specifications. This radical new design optimizes flexibility and reliability wile processing high liquid loads with exceptional solid particle handling.

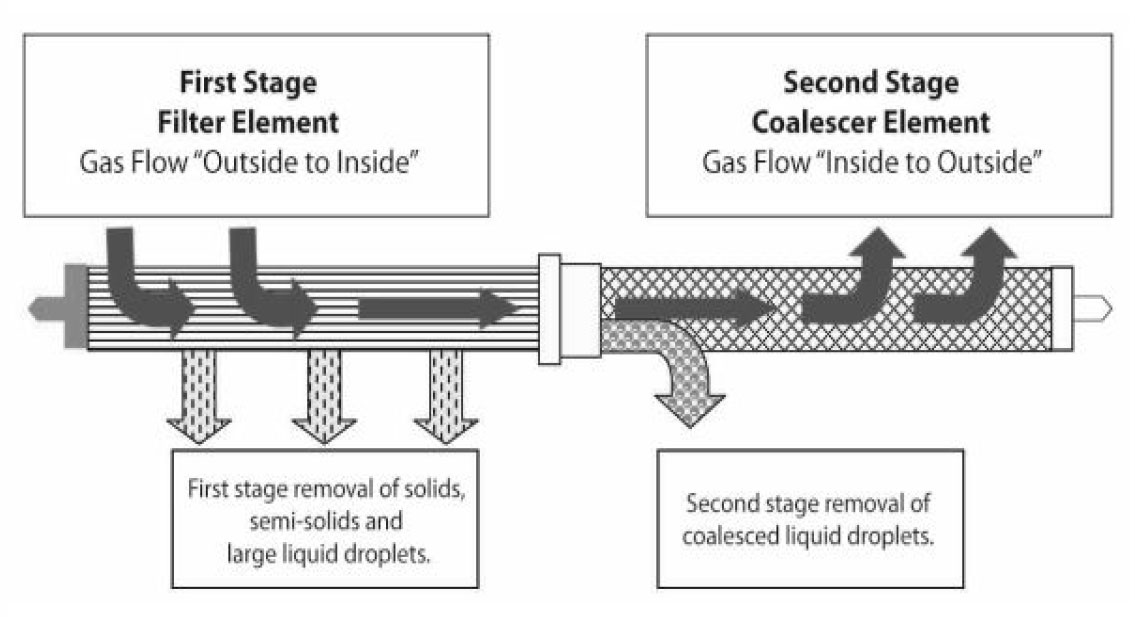

Design to remove solid and liquid contaminants from natural and process gas, the assembled SecureLock cartridges provides both a first stage “outside to inside” flow direction filter element and a second stage “inside to outside” flow coalescer element. The SecureLock allows the option to replace and optimize the first stage without having to replace the second one. All SecureLock cartridges incorporate and extensive list of optional filters and coalescing elements combination that can be tailored to suit individual process applications.

Features

- Efficient removal of aerosols and liquids to protect downstream equipment.

- Permits replacement of the first stage filter elements while the second stage coalescing element remains in the vessel.

- SecureLock integrated solid shields help prevent solids build up behind the gasket allowing for an easier removal of the

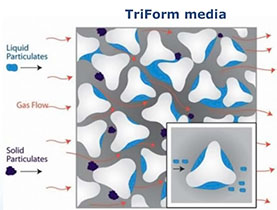

elements. - Innovative TriForm trilobal synthetic fibers provide greater contaminant holding capability.

- Specifically design dust guards strengthens and helps prevent element collapse and gasket failure.

- Allows numerous combinations of cartridges for the ideal blend of filtration, coalescing and drainage characteristics.

- Allows the operator to customize the cartridge in real time with the best pairing of filter/coalescer elements to suit specific process needs.

- SecureLock 1st and 2nd stage elements are approximately half of the length of traditional units reducing both shipping costs and damage to elements during transport.

Applications

- Refining/Petrochemical.

- Gas processing.

- Water treatment.

- Industrial.

- Exploration/production.

- Offshore/Marine.

- Power generation.

- Alternative energy.

SecureLock 1st stage applications

The 1st stage is design to remove solids and semi-solid particulates and pre-coalesce liquids. This process performance and minimizes flow blockage in the 2nd stage element. This function allows the 2nd stage element to operate at peak performance over an extended time. Ölof offers a wide variety of options in both pleated or depth style filters to cover every application and compatibility requirement.

First stage medias available

- TriForm

- Micro glass

- Micro glass ultra

- Polyester

- Polypropylene

- Cellulose

- Cotton

- Costumed

SecureLock 2nd stage applications

The 2nd stage is design as an ultra-high efficiency coalescers for the removal of sub-micron low surface tension liquids. Ölof offers a wide variety of high efficiency second stage coalescers elements in pleated or depth and custom styles to suit every application.

Second stage medias available

- TriForm

- Micro glass

- Micro glass ultra

- Polypropylene

- Polyester

- Costumed engineered

TriForm media

TriForm fiber extrusions process uses synthetic trilobal fibers providing increased void spaces for contaminant retention over traditional circular fiber medias. This TriForm fiber are available both in polyester and polypropylene providing excellent mechanical and chemical resistance.