ÖlofPleat O&G Process elements have been developed to be used in Oil & Gas industry. We know how critical is to protect the assets that produce, transport and process oil and gas, as well as their derivate and finished products.

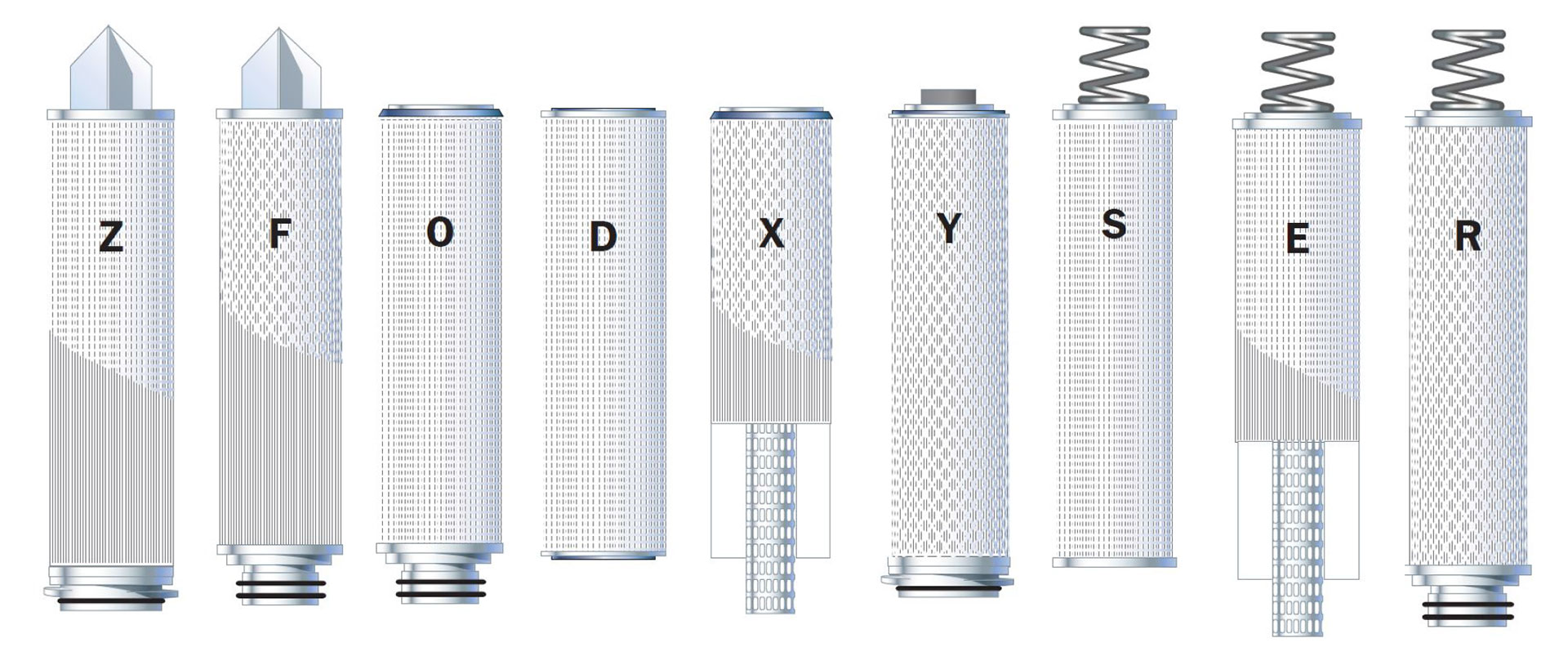

We handle a wide variety of filters elements with different construction materials, couplings and extras so your process will be maintained in the quality standards you are accustomed.

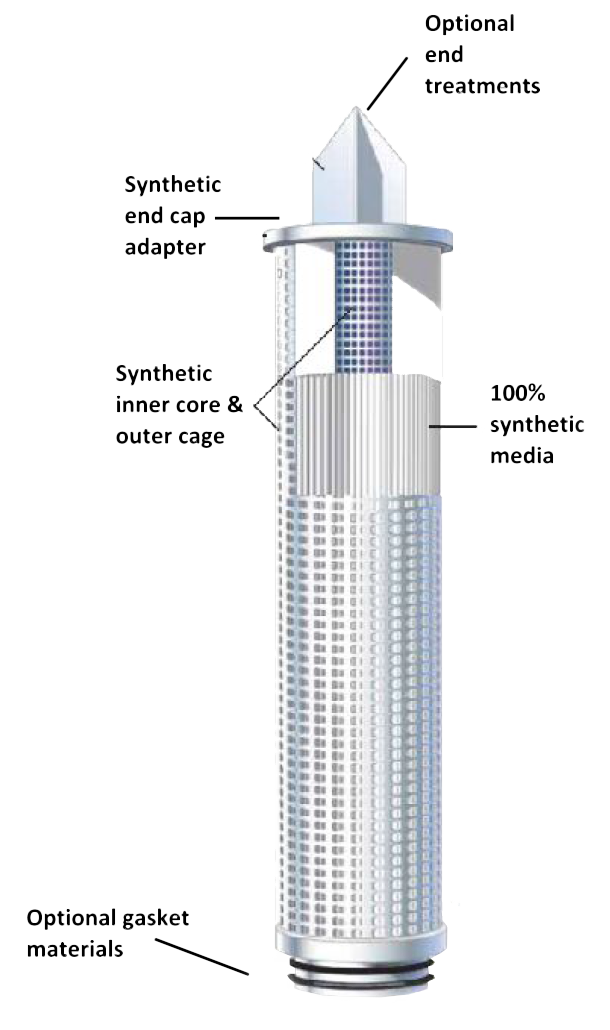

Features

- High effective filtering area, low initial differential pressure and excellent retention capacity of contaminants.

- Nominal rated filter.

- Construction by 100% thermo-bonded elements to increase the element integrity and strength.

- Increased overall process performance.

- Decreased Downtime.

- Lower maintenance costs.

- Internal central support, unique in high flow filters, for a great resistance in high pressures.

- Low maintenance frequency and less number of cartridges needed.

- Available in ratings from 1 to 70 microns depending on the filter selected.

- Reduces drastically the space normally used for filtering systems.

- Wide chemical compatibility.

Standard Applications

- General Water

- Amine Filtration

- Glycol filtration

- Catalyst Recovery

- Solvents

- RO-Prefiltration

- Injection Water

- High Purity Chemicals

- Waste Water

- Process Water

- Lube Oil

- Final Products

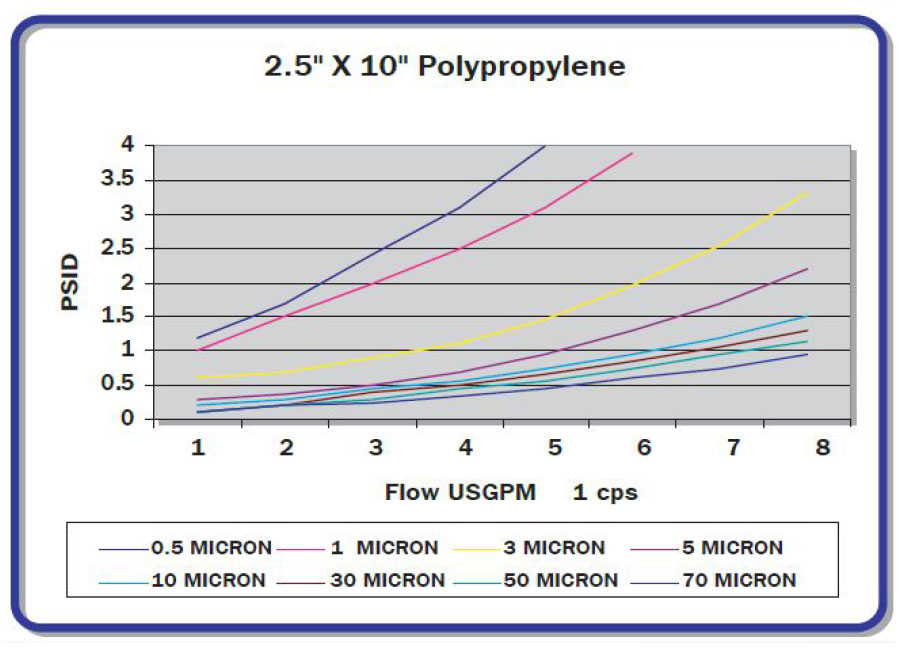

ÖlofPleat - P

Pleated Polypropylene are 100% polypropylene with a wide variety of gaskets and O-rings. Thermally bonded end caps to reduce any interaction with adhesives. βeta ratios from 50 to 5000 for flexibility to address specific applications or upset condition.

- Temperature limit: 180° C.

- Efficiencies: 0.5, 1, 3, 5, 10, 20, 30, 40, 70 μm.

- βeta radios: 50, 100, 200, 1000, 5000.

- All components meet USP specifications for Class VI 121°C criteria and are FDA complaint.

- Rating above 30 μm do not require support layers.

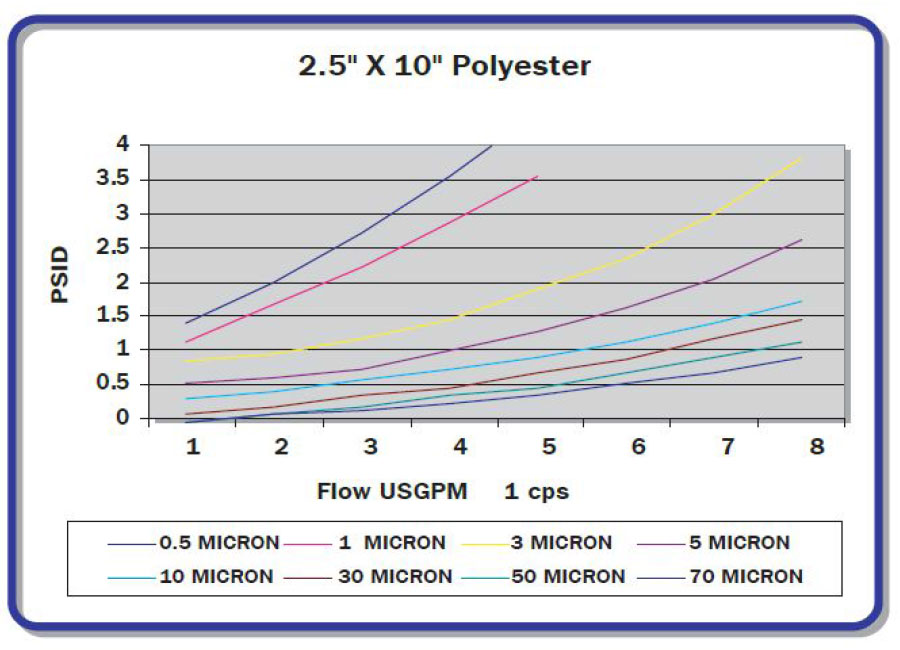

ÖlofPleat - E

Pleated Polyester are 100% polyester with a wide variety of gaskets and O-rings. Thermally bonded end caps to reduce any interaction with adhesives. βeta ratios from 50 to 5000 for flexibility to address specific applications or upset condition.

- Temperature limit: 240° C.

- Efficiencies: 0.5, 1, 3, 5, 10, 20, 30, 40, 70 μm.

- βeta radios: 50, 100, 200, 1000, 5000.

- All components meet USP specifications for Class VI 121°C criteria and are FDA complaint.

- Rating above 30 μm do not require support layers.

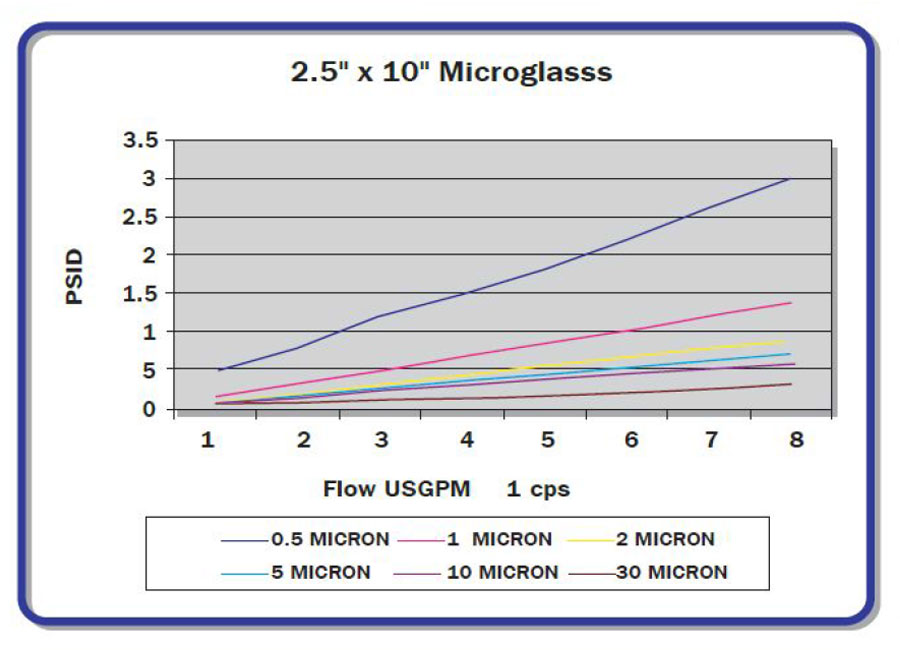

ÖlofPleat - G

Pleated Microglass are 100% glass fibers with a phenolic binder that provides excellent strength in many liquid applications. Support layers are standard polyester or are available in polypropylene or cellulose to suit temperature requirements with a wide selection of elastomers. Polypropylene or Polyester end caps and cores are thermally bonded to media pack. Alternative, end caps are plated or stainless steel bonded to the media packs using either plastisol or two part epoxy to secure the media pack.

- Temperature limit: 275° C.

- Efficiencies: 0.5, 1, 2, 5, 10, 20, 30, 40μm.

- βeta radios: 50, 100, 200, 1000, 5000.

ÖlofPleat - K

Pleated composite liquid elements.

This are a blend of synthetic and cellulose fibers which provides various advantages over common cellulose media including superior performance in aqueous applications. Thermally bonded end caps to the media to reduce any interaction with adhesives. Plated carbon steel or stainless steel end caps are available using plastisol or two part epoxy to secure the media pack. A broad range of media from 0.5 to 70 microns and βeta ratios of 50 to 1000.